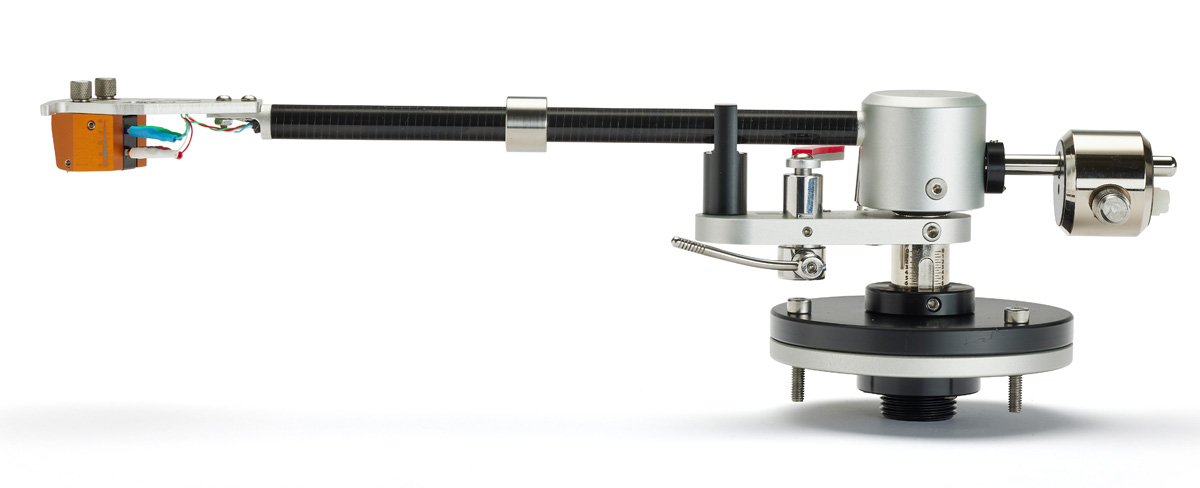

Super Groove Precision Tonearm

Benefitting enormously from the work done in developing the Reference Tonearm, the Vertere Super Groove PTA offers incomparable performance in almost any class

To achieve breath-taking musical performance, the Vertere Super Groove Precision Tonearm utilises a combination of quality materials including roll-wrapped carbon-fibre, stainless steel, brass, aluminium alloys and silicon nitride.

Its unique bearing design and versatile anti-skate adjustment make it an ideal partner for highest quality cartridges and turntables

Why Super Groove Precision Tonearm?

- New unique precision Tri-Pivot Articulated, ultra-low stiction bearing.

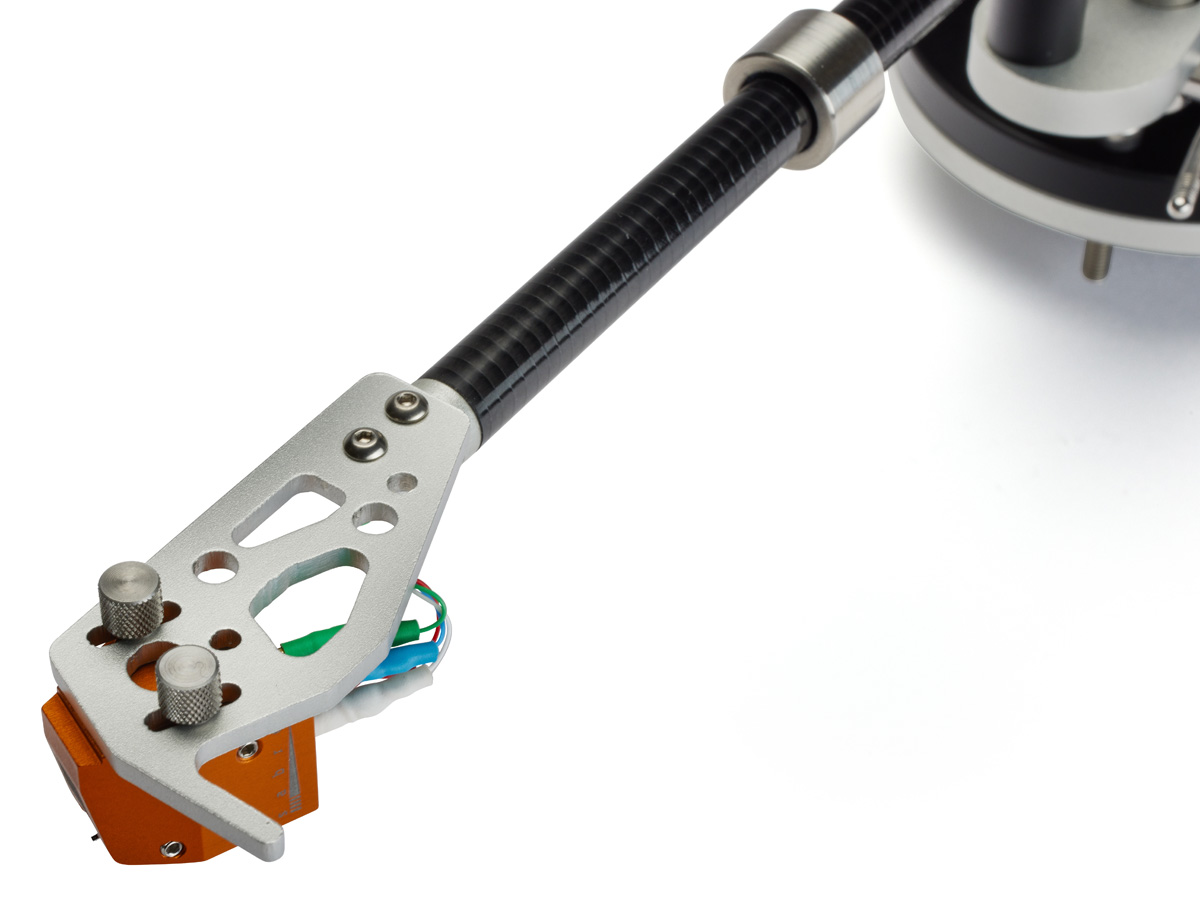

- New Aluminium head-shell.

- New heavier decoupled main counterweight with fine azimuth adjustment screw.

- New fine-tuning of tracking weight and arm/cartridge resonance control adjustment weight ring.

- New connections all custom manufactured and triple gold-plated.

- Non-resonant, high-rigidity roll-wrapped carbon fibre arm tube.

- Bias-curve adjustable anti-skate mechanism.

- Custom Vertere internal wiring

SG-TPA Tonearm Bearing

The unique Tri-Pivot Articulated (TPA) bearing is comprised of three precision silicon nitride balls captive in a precision machined Acetal ball retaining ring supporting the super precision machined stainless pivot.

The pivot point centred between the silicon nitride balls provides flawless support and articulation.

TPA eliminates bearing point ‘skating’ and allows the stylus to track the most delicate pieces of information that are typically lost with uni-pivot designs.

This ensures accurate play back due to the strict adherence of the stylus to the record groove.

SG-PTA Tonearm Tube & Head-shell

Roll wrapped carbon fibre is used in the construction of the arm tube.

This provides higher strength and more homogenous fibre structure than a Pultruded or moulded equivalent.

The head-shell is made from aluminium alloy and connected to the arm tube via structurally bonded alloy end insert.

Naturally non-resonant and higher strength to weight ratio of this configuration provides the optimum cartridge platform.

Aluminium Bearing Yoke and Brass Pillar

The bearing pivot is structurally bonded to the precision machined aluminium alloy yoke.

The assembly provides the support required for the arm tube, the main counterweight and the anti-skate mechanism.

The pivot point and the counterweight centre of gravity are vertically positioned to be as low as possible.

This in turn retains the tonearm in its most stable position by the chrome plated brass main tonearm pillar.

Bearing Transit Screw & Counter Weight Locator

SG-PTA tonearm transit screw will prevent any accidental damage to the precision Tri-pivot bearing during shipping.

And the counterweight locator will ensure accurate repositioning of the counterweight and eliminate the need to setup the Tracking Weight & Azimuth again.

Arm/Cartridge Resonance Frequency & Fine Tracking Weight Adjustment

An adjustable and de-coupled stainless ring allowed to move along the arm tube provides fine tracking weight adjustment.

The relative position of this ring and of the main counterweight can also be used to alter the arm/cartridge resonance frequency and optimise play back performance of the cartridge.

SG-PTA Tonearm Main Counterweight

Attention to detail is clearly seen in the mirror chrome plated brass counterweight and polished stainless steel peg.

Two pairs of silicone de-coupling rings are utilised to provide the necessary grip for location and the required isolation of the counterweight.

Side-to-side moving and lockable Fine Adjustment Azimuth Screw offers easy and accurate setting of the cartridge azimuth to ensure optimum musical performance.

SG-PTA Tonearm Pillar Holder and Clamp

Precision machined from Acetal the SG Tonearm Pillar Holder and Clamp utilises a Tri-point fixing method to provide the tonearm/cartridge the required interface rigidly coupled to the record player.

Internal Wiring & Contact Connectors

Both the cartridge tags and the 5-pin connector pins are designed, machined and gold plated to Vertere exact specifications for the SG PTA tonearm. The 5-pin connector main body is also machined form solid PTFE for its superior di-electric characteristics. SG-PTA tonearm is internally wired with Vertere Pulse wiring.

Specifications Super Groove Precision Tonearm

Type

Tri Point Articulated

Effective Length

240mm

Overhang

17.5mm

Offset Angle

22.9°

Head-Shell

Aluminium Alloy

Arm Tube

Wrapped Carbon Fibre

Bearing Yoke Structure

Aluminium Body

Bearing Type

Captive silicon Nitride Ball (x3) Precision

Counter Weight

Mirror Chromed Brass

Stainless Steel T/W Adj. Sleeve

Internal Wiring

Vertere Pulse Wiring

Connector

Proprietary Cartridge Tags & 5-Pin

x3 Thickness Gold Plated Contacts

Tonearm Cable

Optional: PULSE HB, veRum or Redline

Weight

428g